LDC

Drop-thru compact Rotary Valve for powder 0,1 bar differential pressure

- Very large inlet in relation to the rotor volume

- Low overall height

- Heavy duty construction

- Outboard bearings and packing gland type seals

- High temperature versions up to 350 °C

- Versions in accordance with 2014/34/EU

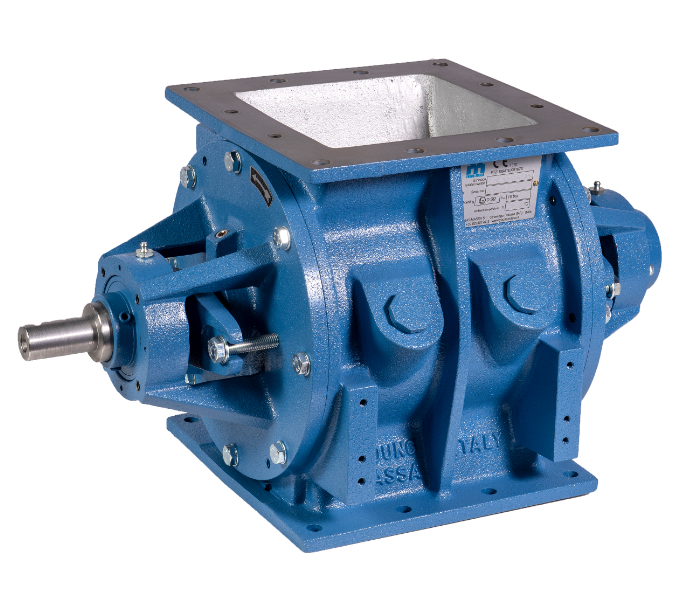

DC

Drop-thru Rotary Valve for powder 0,1 bar differential pressure

- Heavy duty construction

- Cast iron body

- Large inlet and outlet

- Outboard bearings and packing gland type seals

- High temperature versions up to 350° C

- Versions in accordance with ATEX 2014/34/EU

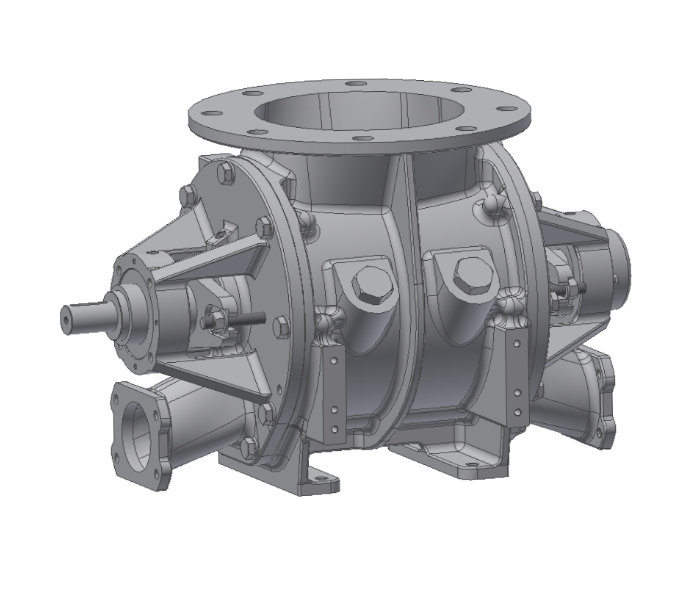

LDT

Drop-thru Rotary Valve for powder 1 bar differential pressure

- High filling efficiency

- Minimum gas leakage

- Heavy duty construction

- Cast iron body

- Outboard bearings and air purge type seals

- Explosion proof versions up to 10 bar and St2 products

- Versions in accordance with ATEX 2014/34/EU

- Fast opening versions avaible

LDR

Drop-thru Rotary Valve for powder 1 bar differential pressure Round inlet/outlet DIN PN10

- High filling efficiency

- Minimum gas leakage

- Heavy duty construction

- Cast iron or stainless steel body

- Outboard bearings and air purge type seals

- Flanges in accordance with DIN PN10 or ANSI 150

- Explosion proof versions up to 10 bar and St2 products

- Versions in accordance with ATEX 2014/34/EU

- Fast opening versions available

LBT

Blow-thru Rotary Valve for powder 1 bar differential pressure

- High filling efficiency

- Minimum gas leakage

- Heavy duty construction

- Cast iron body

- Outboard bearings and air purge type seals

- Optimized entrainment trough

- Versions in accordance with ATEX 2014/34/EU

- Fast opening versions available

LBR

Blow-thru Rotary Valve for powder 1 bar differential pressure Round inlet DIN PN10

- High filling efficiency

- Minimum gas leakage

- Heavy duty construction

- Stainless steel body

- Outboard bearings and air purge type seals

- Flange in accordance with DIN PN10 or ANSI 150

- Optimized entrainment trough

- Versions in accordance with ATEX 2014/34/EU

- Fast opening versions available

LSE

Offset inlet Rotary Valve for pellets and grains 1 bar differential pressure

- Offset inlet for safe starting under head of product

- No product shear degradation

- Adjustable feed rating slide plate at the inlet

- Minimum gas leakage

- Heavy duty construction

- Carbon steel or stainless steel body

- Versions in accordance with ATEX 2014/34/EU

- Fast opening versions available

LDT, LDR EN15089

Explosion isolation Rotary Valve for dust St2 – 10 bar

- Explosion and flame proof for dusts St1 and St2

- Pressure shock resistant up to 10bar

- In accordance with EN15089– Ex D St2

- In accordance with ATEX 2014/34/EU

LDTS

Fast opening Rotary Valve for easy internal cleaning

- Fast opening for easy internal cleaning

- Double sided coupling at the rotor shaft

- Outboard bearings and air purge type seals

- Open end rotor with 10 chamfered blades

- Cast iron body

- Explosion proof versions up to 10bar and St2 products

- Versions in accordance with ATEX 2014/34/EU

- Direct drive or chain drive

LDRS

Fast opening Rotary Valve for easy internal cleaning

- Fast opening for easy internal cleaning

- Double sided coupling at the rotor shaft

- Outboard bearings and air purge type seals

- Open end rotor with 10 chamfered blades

- Cast iron or stainless steel body

- Sanitary versions available

- Explosion proof versions up to 10bar and St2 products

- Versions in accordance with ATEX 2014/34/EU

- Direct drive or chain drive

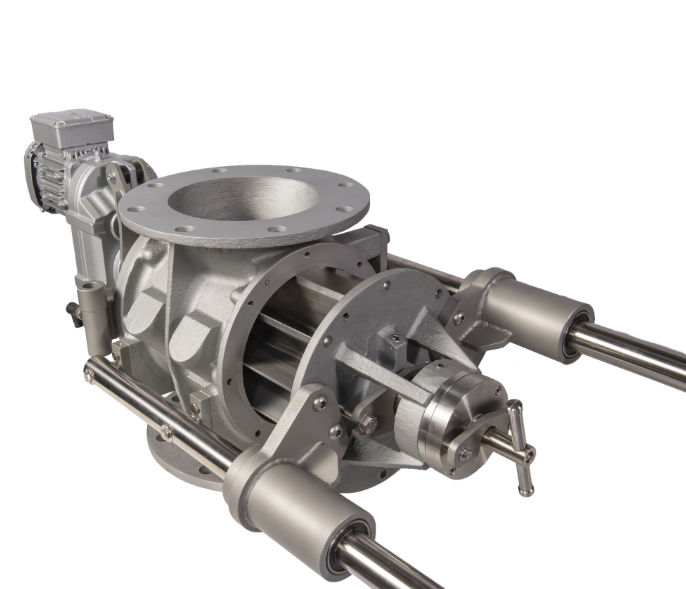

LDRZ

Fast opening Rotary Valve with supporting bars

- Easy removal of rotor and end cover without lifting

- Safe and easy cleaning of internal surfaces

- Stainless steel body

- Sanitary versions available

- Explosion proof versions up to 10bar and St2 products

- Versions in accordance with ATEX 2014/34/EU